Ammonia Scrubber Design Calculation

Ammonia scrubber design calculation. Chemical manufacturers are required to reduce their ammonia gas emissions because it is classified as a hazardous substance by the United States Emergency Planning and Community Right-to-Know Act EPCRA. CS-35 Ammonia Scrubber Cut Sheet Ammonia Scrubber Systems Tailored to Achieve YOUR Goals. Aqueous NH3 solutions are characterized by relatively high NH3 vapor pressures that prevent the mass transfer of NH3 from gas to liquid phase.

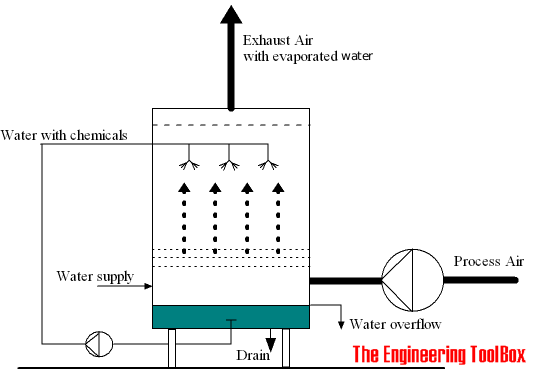

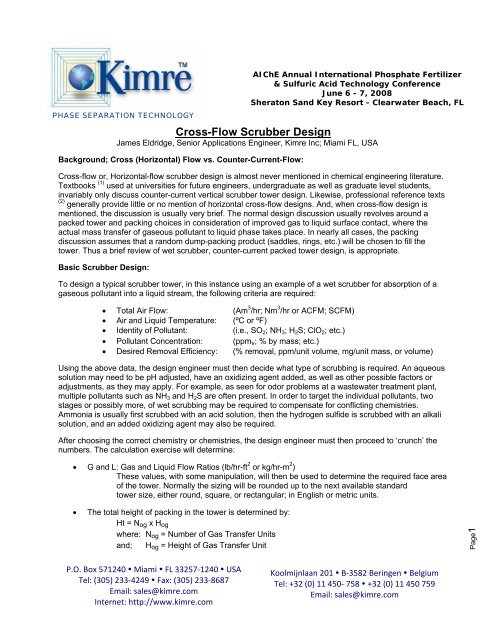

AbstractNote A continuous gas and liquid flow regenerative scrubbing process for CO sub 2 capture was demonstrated at the bench-scale level. μ h scrubber humidifying efficiency t 1 initial dry bulb temperature o C t 2 final dry bulb temperature o C t w initial wet bulb temperature o C Scrubber Efficiencies. Our primary sustainability challenge is to reduce the calculated water consumption of 158900 gpd gallons per day without compromising performance.

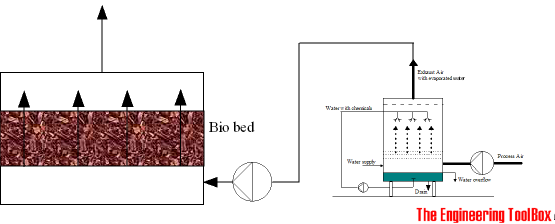

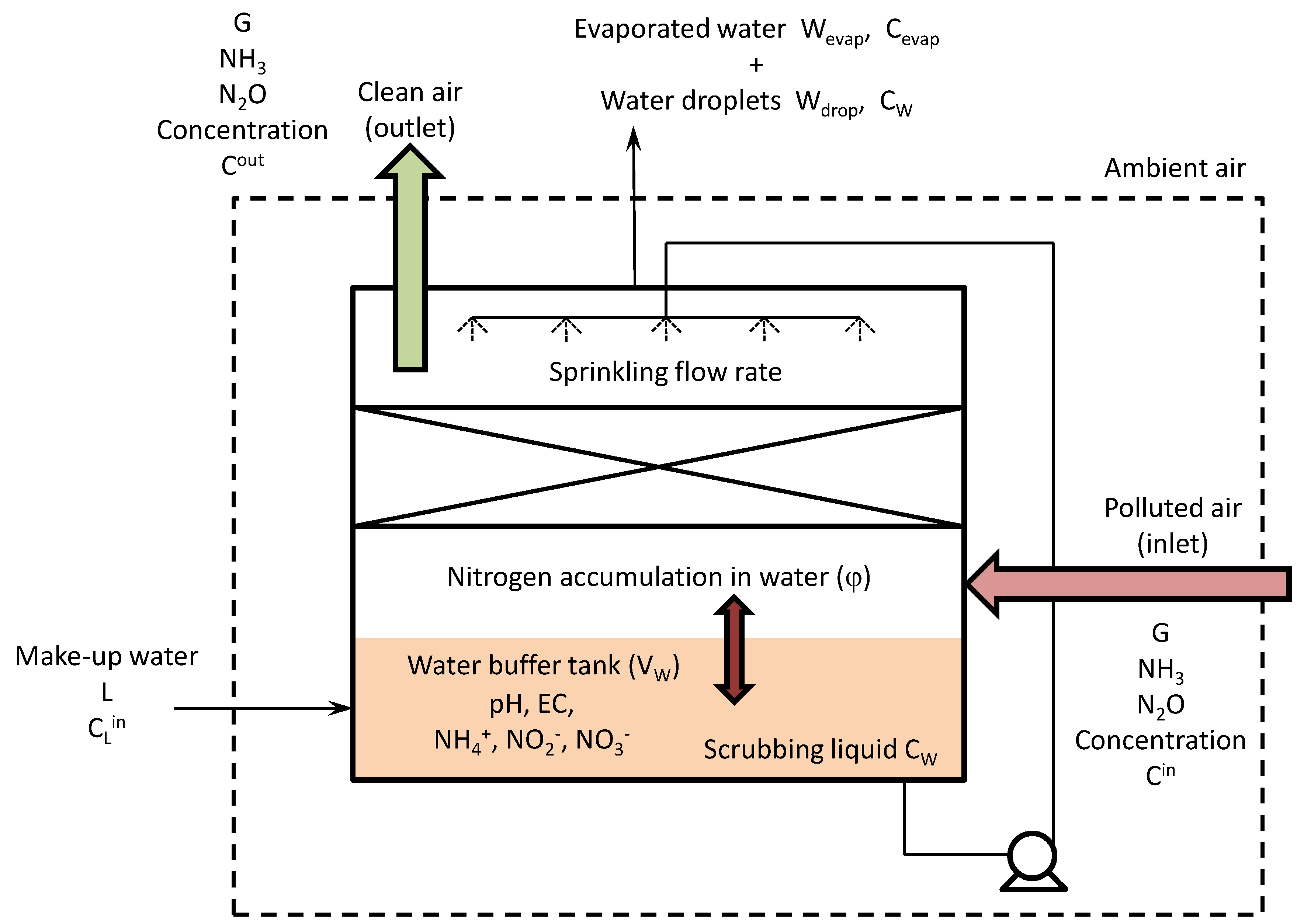

Acid scrubbers and biotrickling filters have been developed for ammonia NH 3 removal at pig and poultry houses in The Netherlands over the last 20 years to prevent acidification and eutrophication of soils. Ammonia is a compound of nitrogen and hydrogen. Ammonia IDLH Value 300 ppmv.

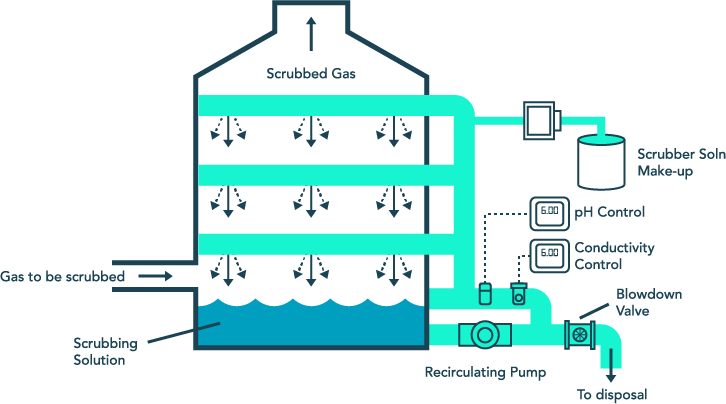

Selectivity calculations are fundamental to the success of the treating process and to minimize caus-tic consumptionCO 2 pickup. After the regeneration the solution of ammonium compounds is recycled to the absorber. What are Ammonia Scrubbers and How Do They Work.

The high content of carbon dioxide and the presence of hydrogen sulphide and ammonia make it unsuitable to be used in place of natural gas in gas distribution networks. If ammonia is present in the feed gas some may be absorbed into liquid phase in a caustic scrubber although the high pH of caustic scrubbers. Industrial ammonia is sold as either an ammonia liquor or as a pressurized andor refrigerated anhydrous liquid ammonia transported in Ammonia Scrubber tanks cars or cylinders.

That study tested fairly high acid levels 005 to 06 N. An aqueous ammonia-based solution captures CO sub 2 from simulated flue gas in an absorber and releases a nearly pure stream of CO sub 2 in the regenerator. And ammonia 1 6.

The humidifying efficiency of the scrubber may be expressed as. Call Purafil to help you transform your caustic wet scrubber to a safe dry scrubber with our patented retrofit plan.

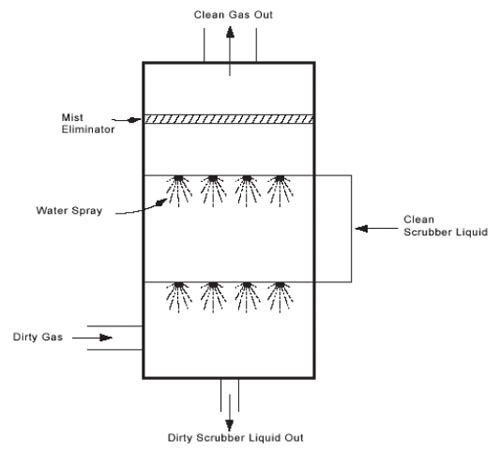

Typical nozzle scrubber efficiencies.

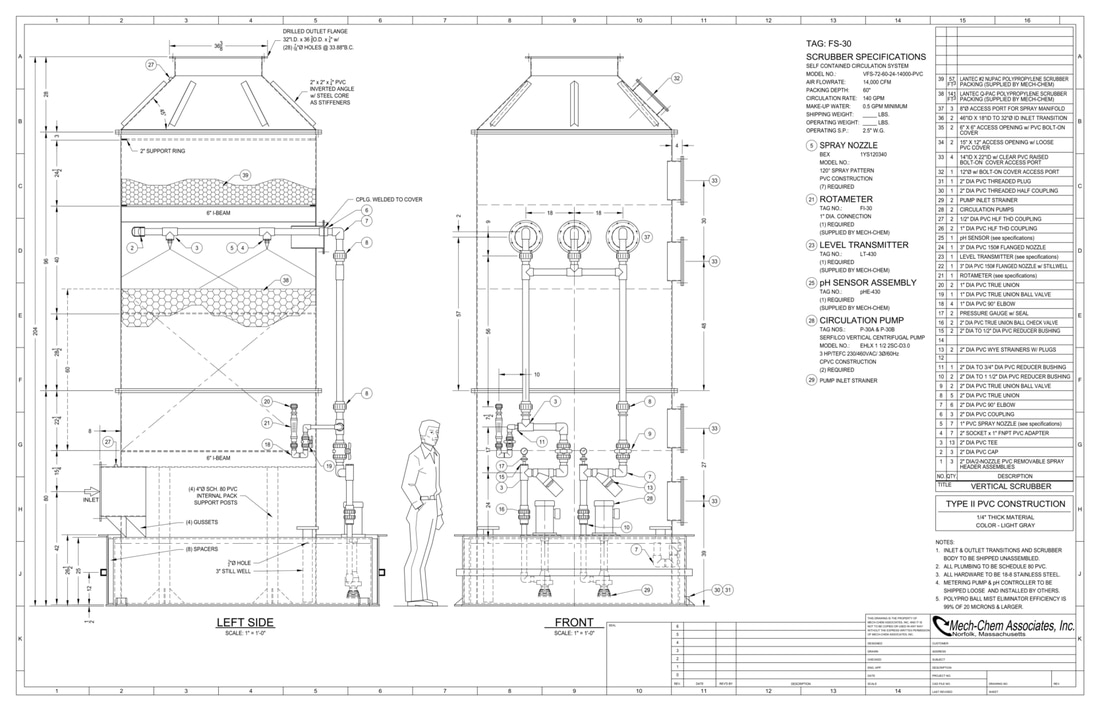

Selectivity calculations are fundamental to the success of the treating process and to minimize caus-tic consumptionCO 2 pickup. That study tested fairly high acid levels 005 to 06 N. Now Outlet flowrate of gas through the column G 004 x ρg ρl-ρggc Cf x μl01 x J05 16665 KgSqmSec Pl dont confuse between the initial G and the current G the initial G ie X-axis will represent the inlet flowrate of gas and the Y - axis G will represent the outlet flowrate of gas. μ h scrubber humidifying efficiency t 1 initial dry bulb temperature o C t 2 final dry bulb temperature o C t w initial wet bulb temperature o C Scrubber Efficiencies. Typical nozzle scrubber efficiencies. Chemical manufacturers are required to reduce their ammonia gas emissions because it is classified as a hazardous substance by the United States Emergency Planning and Community Right-to-Know Act EPCRA. Ammonia NH 3 is readily scrubbed using Jet Venturi Packed Towers or Multi-channel Bed ScrubbersAlthough ammonia is infinitely soluble in water recirculating an aqueous NH3 solution cannot generally be used for scrubbing. CS-35 Ammonia Scrubber Cut Sheet Ammonia Scrubber Systems Tailored to Achieve YOUR Goals. Purafils EGS design can provide discharge concentrations as much as 100x lower than representative wet scrubbers.

Our primary sustainability challenge is to reduce the calculated water consumption of 158900 gpd gallons per day without compromising performance. What are Ammonia Scrubbers and How Do They Work. Systems are custom sized and designed design temperature and pressure will be accounted for on an individual basis. Because of growing suburbanization odor removal is increasingly considered important as well. Acid scrubbers and biotrickling filters have been developed for ammonia NH 3 removal at pig and poultry houses in The Netherlands over the last 20 years to prevent acidification and eutrophication of soils. Now Outlet flowrate of gas through the column G 004 x ρg ρl-ρggc Cf x μl01 x J05 16665 KgSqmSec Pl dont confuse between the initial G and the current G the initial G ie X-axis will represent the inlet flowrate of gas and the Y - axis G will represent the outlet flowrate of gas. Ammonia Odor Threshold 5 ppmv.

Post a Comment for "Ammonia Scrubber Design Calculation"